CSEM – Coating for batteries

CSEM possesses a strong technological offer in the field of nano-coatings and functional surfaces. Our know-how regarding surface and interfacial modification is well established and highly appreciated by our industrial customers.

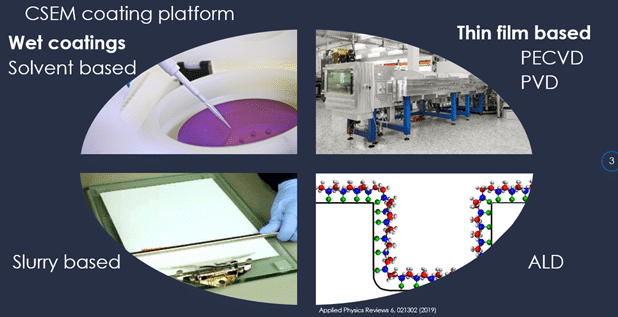

These competences are well supported by our characterization capabilities as well as our equipment and infrastructure for thin film deposition. Specifically, for battery applications, several coating processes, whether wet (spin-, spray-, slot-die or blade-coating, sol-gel formulation, mesoporous coatings) or vacuum based (ALD, PVD, MVD) can be used to improve battery performances for example by working on separator or electrode components. CSEM also possesses know-how of surface functionalization and interfacial engineering, recognized as keys for improving the performance, stability, and even safety of batteries. To validate such developments, coin cells can be fabricated to investigate the influence of material properties on the cell-level performances. Characterization of the electrochemical performance of the coatings (cyclic voltammetry) is notably available, while coin cell characterization is done by using Electrochemical Impedance Spectroscopy (EIS) to observe transfer proprieties of electrodes and separators.

Andrea Ingenito

Sector Head

Jaquet-Droz 1

2000 Neuchâtel

Switzerland